Modernization of a municipal boiler house in Szydłowiec, Poland

Place of implementation: Poland

Poland is currently facing a serious problem: it is one of the countries with the highest levels of air pollution in Europe and the world. The main reason for this is the large-scale burning of coal and lignite, often in outdated and inefficient boilers. The standards set by the Polish government are exceeded in many cities, and pollutant levels are often hundreds of percent above these limits. As a result of this situation, Polish cities are at the top of the list of the most polluted places in the world, especially in windless weather.

Ensuring clean heat has therefore become an important issue for the Polish government in recent years. The aim of these efforts is not only to improve air quality but also to increase the efficiency of heat generation. These factors were the main motivation for the conversion of the municipal boiler house in Szydłowiec.

About the project

The client for the conversion of the municipal boiler house in 2021 was Ciepłownia Szydłowiec Sp. z o.o. which is wholly owned by the city. The aim of this project is to completely modernize the city’s heating system. The solutions used are primarily intended to minimize negative environmental impacts, increase the overall production efficiency, and thus significantly reduce the cost of heat production in the city.

Cogeneration solution

Before the reconstruction, the district heating plant operated an outdated and non-environmentally friendly boiler house equipped with three coal-fired boilers that provided water heating. These boilers have been in operation since 1984. In addition, one of them had been scrapped in the past due to its poor technical condition.

We entered the tender, prepared the entire project, and submitted it together with our long-standing Polish partner, Zakład Innowacyjny technik energetycznych Promat Sp. z o.o. which will also provide maintenance and service for the entire system in the future.

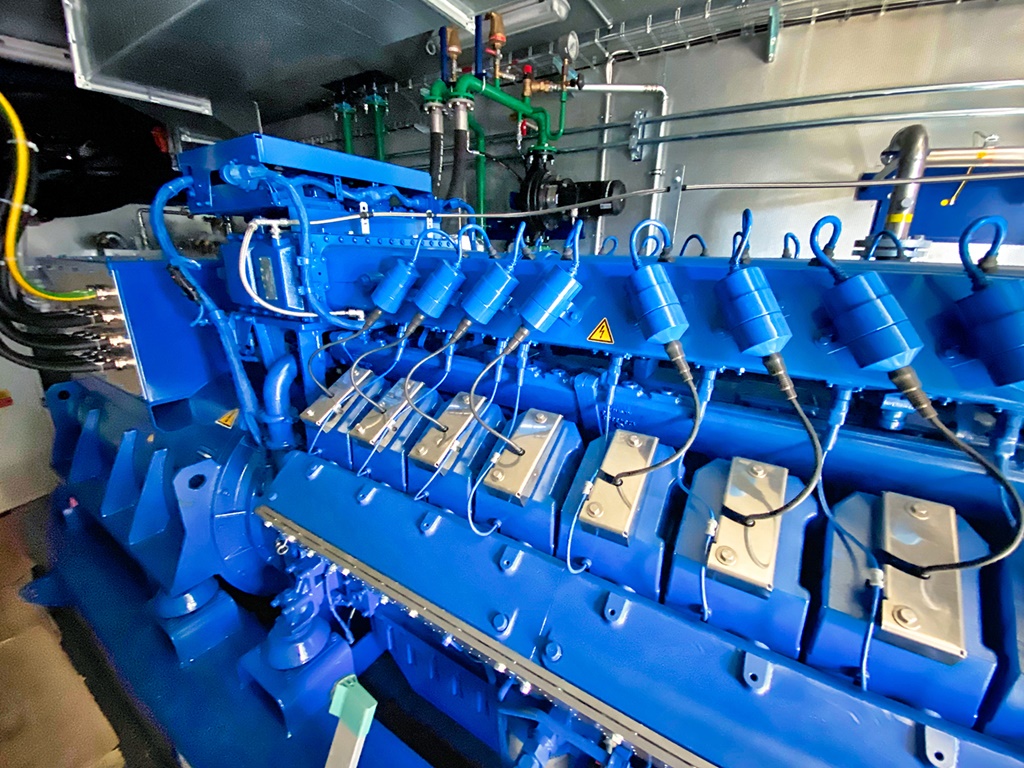

The CHP unit produces heat for the district heating network and electric power that the district heating plant supplies to the national grid which constitutes its additional income. The unit includes online monitoring services, which allow the operator to comfortably control it remotely.

Natural gas CHP unit

Excess electricity as an additional source of income

Online monitoring and control of the CHP unit

Current status

The CHP unit was commissioned at the end of 2022 and currently (October 2023) has endured over 5,500 hours of operation. The environmental effect of the whole boiler house project is to reduce carbon dioxide emissions by more than 6,000 tons per year.

Online monitoring of the boiler room allows the CHP unit to work with other energy sources in the area, which together manage consumption to reduce the overall environmental burden. This system includes a coal-fired power plant and several solar energy sources in the vicinity.

„TEDOM has met our every expectation as a consortium contractor for the task“.

Dariusz Podgórski, Chairman of the Board of Directors of Ciepłownia Szydłowiec Sp. z o.o.

More case studies

Selected references and case studies